Address

304 North Cardinal St.

Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal St.

Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

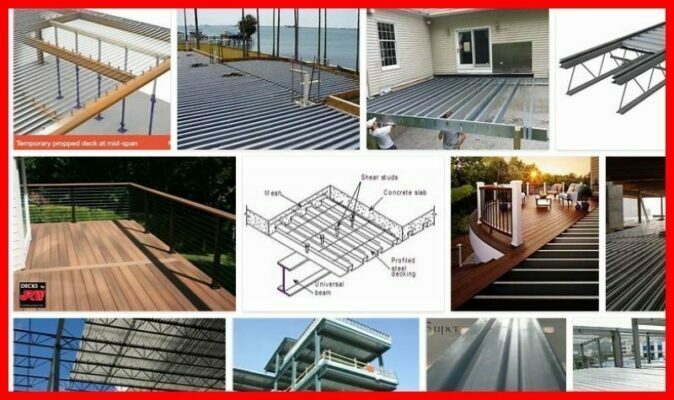

There are several advantages of a Composite Steel Deck. It is fast to install, and there are fewer crane lifts than with a precast slab. Its ability to be stacked into bundles is also a benefit in reducing transport time and cost. Moreover, the decking can be used as a working platform and restrain steel beams from lateral torsional buckling. It is a versatile solution for a variety of purposes.

Despite the many benefits of a Composite Steel Deck, it is important to follow certain design criteria. It must have the bending capacity of concrete and resist out-of-plane gravity loads, which are usually superimposed dead and live loads, concrete, and the self-weight of the deck. To measure the strength of a composite steel roof or deck, ANSI/SDI C-2011 and Full scale performance testing provide details. These tests are performed to determine the deflection of a composite steel beam or deck under a superimposed load, as prescribed by building codes. These codes generally limit deflection to L/360 during the service life of a composite steel deck.

Another important feature of a Composite Steel Deck is its ability to resist out-of-plane gravity loads. Often, these are superimposed dead and live loads on a concrete slab or girder. The deck must also be able to resist these forces. The two methods described in ACI 318 are primarily based on the strength of the composite system and the bending strength of the deck. Regardless of the method, the deflection of a composite steel floor is limited to L/360 in a single span of concrete.

While Steel Deck are not necessarily required to fill gaps between the deck and the concrete slab, they should have high-bending capacity and be able to withstand out-of-plane gravity loads. These forces are often superimposed on a concrete slab and are typically tensile. Using various methods, the bending strength of a composite floor deck must be tested according to building codes. This is because a deflection can reduce the structural integrity of a structure.

The main advantage of a Composite Steel Deck is its ability to withstand extreme weather conditions and can span four to sixteen feet between beams. The most common steel decks are made of ASTM A653/A1008 structural sheets, which are designed to have a minimum yield strength of 33ksi. The material properties of a deck determine the strength and stiffness of the deck. The thickness of the steel deck is specified by the dimensional thickness or gage.

Depending on the application, a Steel Deck may require a wire mesh as a means of controlling cracks. While wire mesh is not the ideal option for preventing cracks, it has been endorsed by the Steel Deck Institute. As long as it is incorporated properly, wire mesh can limit the width of a crack at the floor surface. However, wire-mesh requires extensive lapping and high support in the slab. It also suffers from five significant drawbacks.