Address

304 North Cardinal St.

Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal St.

Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

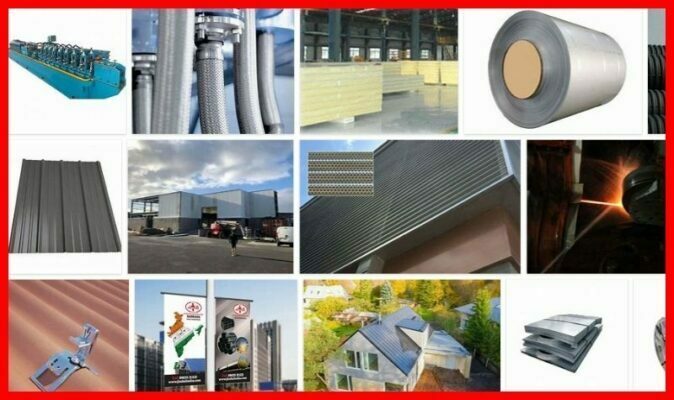

Corrugated Steel Producer are an excellent option for roofing and siding applications. They can be made from light gauge metal or uncoated steel. The former is better suited for outdoor applications as it has higher tensile strength than wood. The latter is ideal for indoor applications as it can withstand a variety of weather conditions. Choosing the right type of sheet material is important for durability and energy efficiency. The following sections describe some of the benefits of corrugated steel.

The process is carried out with a machine called a roll forming machine. This machine is highly automated and achieves a high productivity with little labour. A massive roll of sheet metal is rolled through a series of dies before it is automatically sliced to the desired length. Corrugated Steel Producer metal is traditionally round and wavy, but different dies can create square, rectangular, trapezoidal, and elliptical shapes.

The process of making Corrugated Steel Producer involves the use of roll forming. The process is highly automated, which results in high productivity with low labour costs. The sheets are pulled off of huge rolls and rolled through rolling dies. The metal is automatically cut to the desired length. Most corrugated sheets are circular or wavy, but different dies can produce different shapes and sizes. Industrial buildings and other buildings often use trapezoidal sheet metal.

The corrugation process is a highly automated process that helps manufacturers maintain high productivity while reducing labour costs. The process involves pulling the sheet metal off the roll and through rolling dies. Once the sheet metal is rolled through, it is automatically sliced into the desired length and thickness. While traditionally, the style of corrugated sheet metal is round or wavy, the technology used for the process allows for various other shapes, such as trapezoidal.

Among the advantages of Corrugated Steel Producer sheets is that they look brilliant from the outside. Unlike other types of roofing, these materials offer a variety of benefits, including durability, weather protection, life spawn, and aesthetics. However, there are some drawbacks to using steel as a roofing material. Despite its high price, it is an effective choice for residential roofs. It is also an excellent choice for commercial roofing.

Corrugated Steel Producer sheets are used for many construction purposes. This material is lightweight and inexpensive, and can be painted or coated to improve its appearance. It is ideal for constructing new commercial structures and is a cost-effective option. Most corrugated steel sheet producers in the United States are members of the American Galvanizers Association. The Association’s standardization standards are a great way to prevent the corrosion of the metal.

Corrugated steel has a history dating back to the 1800s. The original material is iron. It can be found in varying thicknesses. For example, a thin corrugated sheet can be as thick as six gauge. It can also be applied to other materials, such as wood. There are a number of advantages to using corrugated steel. The best benefit is that it is easy to maintain. Moreover, it is one of the least expensive types of siding.