Address

304 North Cardinal St.

Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal St.

Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

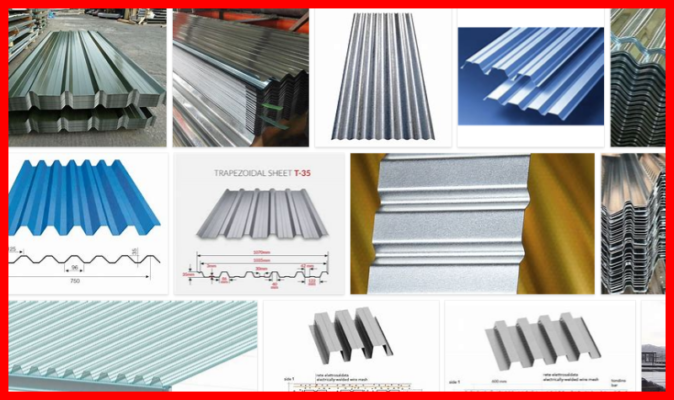

The best way to shape a Corrugated Trapeziodal Steel Sheet is to use two stiffeners on the flange and one on the web. During this process, the stiffeners help the sheet resist compression and increase the load carrying capacity. The study carried out numerical experiments to verify the performance of the trapezoidal sheet according to Eurocode 3 recommendations. Its results are presented in Table 1. This table also includes the details of the various variants.

The optimum cross-section for a Corrugated Trapeziodal Steel Sheet is chosen based on producer requirements. The criterion should be the maximum covering width and bearing capacity while minimizing the metal sheet waste. The study analyzed eight different cross-sections with different widths of plane elements. The number of intermediate stiffeners is based on the buckling factor ks.

A Corrugated Trapeziodal Steel Sheet consists of a flange and a web. The buckling factor is the same for each part. In the first generation, there are no longitudinal stiffeners. In the second generation, intermediate stiffeners are added. Third-generation sheets incorporate intermediate stiffeners. A trapezoidal steel sheet can be used for walls, floors, and roofs. It can also be designed as multi-span systems.

This sheet is available in three main types. A trapezoidal one is the most common and has a trapezoidal profile. Its construction width is 600 – 1,045 mm. Its flanges are interlocked and provide extra support. In addition to these, it is possible to get a corrugated Trapeziodal sheet with a ribbed surface.

The Corrugated Trapeziodal Steel Sheet can be made with or without a flange. The flange and web are connected to each other and are integral. A flange is composed of a flange and a web. It has two main sections: a web and a flange. The web has four sides and a flange is the top layer of the flange. The flange is supported by a double flange.

The Trapeziodal sheet is a common option for roofing materials and is made of steel with a trapezoidal profile. This type of metal sheet has a design that is easy to install. The design flexibility is unmatched by any other material. It can be fabricated from cold-rolled coils and can be customized to suit the specific needs of the customer. The main advantage of using a corrugated steel sheet is that it has a large number of applications.

Besides roofing, the Corrugated Trapeziodal Steel Sheet is often used as structural elements and covering systems. Their thickness can range from 0.5 to 1.5 mm. They are also available in various shapes and sizes. There are three generations of a trapezoidal steel sheet. This is an important consideration in a building’s design. A good quality product will be durable and economical. It is a common choice for building structures.