Address

304 North Cardinal St.

Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal St.

Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

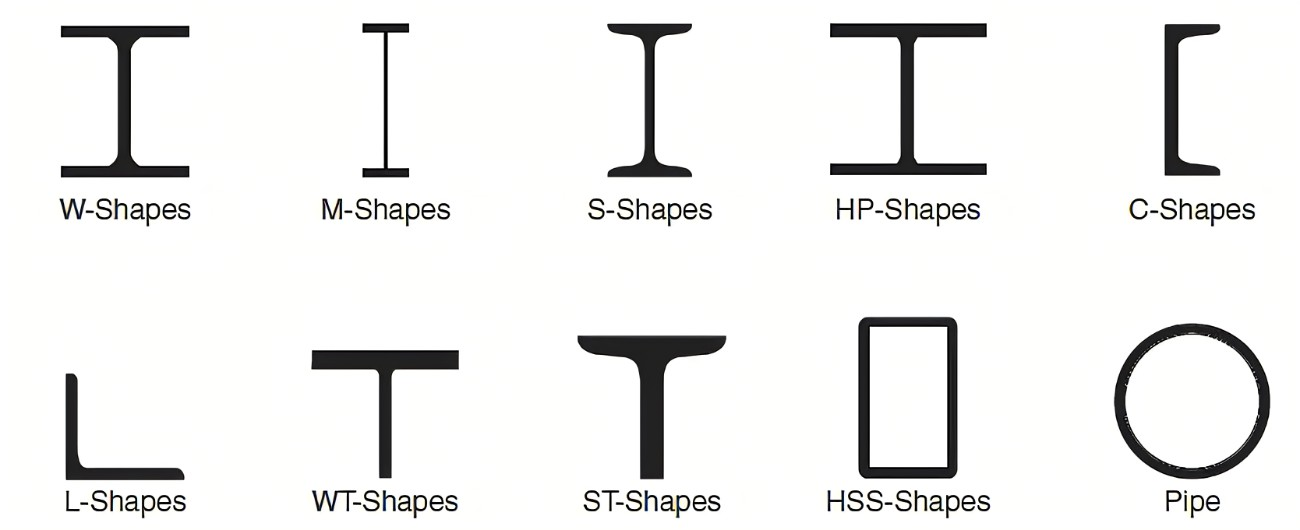

Steel Profile types utilized in steel span development

A few steel profile types are utilized in the development of steel spans. These incorporate Square bars, level bars, C-formed pillars, and L-shape segments. These profiles are made of metals that are known for their solidness and strength.

Different kinds of steel span development utilize L-shape sections. These are like other rectangular or square segment shapes. They offer great help for underlying parts while diminishing development time and cost. They are additionally reasonable for corner sections in limit walls.

Contingent upon the kind of development, development materials, and conduct of the components, the section might have a plenty of shapes. For instance, roundabout sections offer great feel and are in many cases used to help the mainstays of extensions. They likewise offer more prominent protection from twisting than a square or rectangular segment.

The most well-known and most economical section shape is the square. This shape is found in most structure designs, and it is not difficult to project. Yet, it’s anything but a harmless to the ecosystem material.

During the development of steel spans, primary steel radiates assume a significant part. They give the strength and solidness of the construction, while likewise conveying twisting and shear minutes. They are portrayed by their even and rounded cross segments.

These sorts of pillars are utilized in a few applications. They can be produced using wood, metal or cement. They can likewise be solid or composite. They are generally utilized in roadway spans. They are developed in various different cross segment shapes, including square, rectangular, round, and T-formed.

Channel radiates are one more sort of C-molded bar. They are produced using steel and are frequently utilized for supporting and optional outlining. They are many times utilized in load-bearing sections. These pillars are intended to move twisting and pivotal burdens.

Different kinds of square and level bars are utilized in steel span development. They are utilized in different applications including shear support, developed bars, lintels and channels. They are additionally utilized for propping and auxiliary outlining.

The size of the bar fluctuates from 3/16 of an inch to 8 creeps in width. It is normally square in cross segment. In Europe, favored sizes are determined to adjust to Table 6 of standard EN 10080. In the US, ostensible bar breadth is given in 1/8 inch units.

Frequently, the width of a bar is moved to shape a square. These are ordinarily utilized as supporting individuals in light designs.

Furthermore, welded wire texture or welded wire support is additionally utilized. This kind of supporting is alluded to as non-contact joining. These joins might be lapped or butted, or they can be welded.

Contingent upon the strength of the materials used to make it, short supported segments are equipped for conveying loads. They can uphold the upward pivotal burden following up on the focal point of gravity of the cross segment, as well as balanced loads from floor pieces.

There are many sorts of built up sections. Every one is not the same as the other. Notwith standing the size and shape, they are additionally recognized by their underlying way of behaving. The absolute most normal segments incorporate square, round, and rectangular. Other than the shape, they are sorted by their material, including cement, steel, or block.

A substantial section is a design made out of a grid of cement. It conveys twisting pressure from different components like supports or swaggers. Typically, the substantial is built up longitudinally.

Treated steel profiles are turning out to be increasingly more well known for use in span development. They offer many benefits over different materials, including low upkeep and erosion opposition.

As well as being an extraordinary material for spans, treated steel is likewise generally utilized in modern designs. Particularly helpful in regions have unforgiving conditions. It is impervious to consumption, and it can endure elevated degrees of effect without cracking.

Tempered steel is likewise known for its tasteful allure. Its unpainted surface mixes in well with open air conditions. Likewise, the utilization of consumption safe coatings assists with decreasing free time and investigation recurrence.

Tempered steels are a famous decision for developing expressway and railroad spans. They have astounding solidarity to-weight proportions, which helps lower costs. It is additionally impervious to rust, which keeps up with the underlying trustworthiness of extensions.

Generally speaking, there are a few different types of steel profile used in steel bridge construction. These include Stainless steel, Heat-treated carbon steel, Square bars, and Flat bars.

Typically, square steel bars are used in construction projects. They are also commonly used in the assembly of machinery in factories. The material is usually mild steel.

Square bars can be used in a number of different shapes. One of the most common is the T-shape column. They are most often used for bridges. However, the material can also be used for a variety of other civil engineering projects.

Other common shapes are a skew arch, an oblique arch, and a three-hinged arch. The latter is a structure that is hinged at the base of the bridge, which allows the bridge to move at a wide range of angles.

These structures are often designed to accommodate temperature changes. These expansion joints are sometimes tied together with dowels or coatings.

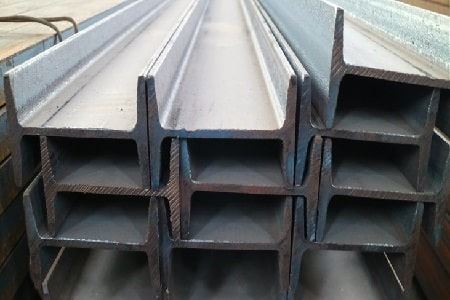

Several different steel profile types are used in the construction of steel bridges. These include columns, beams, I-beams, and universal beams. All are designed to absorb weight and provide strength. The type of reinforcement that is used depends on the design of the structure.

I-beams are structural members with a web and two flanges. They are used in almost all major structures. A W-shaped structural member, or wide flange, is similar to an I-beam but is wider. These are often used in construction because of their versatility.

A T-shape column is the most common for a bridge. They are usually cut in half to produce a wider section. They are also available in unequal angle sections. These are used in both light and heavy applications. They can be built up or welded together to form continuous beams.

HYSD bars and TOR steel bars are popular in the construction industry. They are widely used as reinforcement for concrete structures. They have good tensile strength, corrosion resistance and weldability. They are widely used in bridges, roads and skyscrapers. They can be bent up to 180 degrees without cracking. Compared to mild steel, they have higher yield strength, ductility and tensile strength. They can be used to reinforce mass concrete work and are more cost effective.

HYSD and TOR steel bars are made through a number of heat treatments. The process includes casting, heat rolling, cold twisting, molding, and forming. The result is a bar with a unique shape and deformed surface.

High strength deformed bars are produced in sizes ranging from 4 mm to 50 mm in diameter. They have a harder outer surface and a soft inner core. They are also known as ribbed steel bars.

Using heat-treated carbon steel in bridge construction offers numerous benefits. It is durable, ductile, and has high strength. It is also easy to cut and mold. The lower weight of the material lowers the cost of handling and transporting the material. It is a sustainable material.

Unlike other types of steel, it is recyclable. It is one of the strongest materials available. It is suitable for a wide range of uses. It is affordable, and is used in many manufacturing industries.

Alloys can increase the corrosion resistance, wear resistance, and electrical properties of steel. They can also raise the hot-hardness. In addition, they improve the magnetic properties. These properties allow the use of alloy steel for structural components.

These steels are available in a wide range of grades. Each grade has a specific chemical makeup. The chemical compositions determine the microstructure and properties of the steel.