Address

304 North Cardinal St.

Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal St.

Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Given how often this question occurs, we have no choice but to discuss the procedures that are used in order to determine the quality of the steel. There are many different kinds of metals accessible, and each one is graded based on a different group of quality standards. It may be an essential aspect of the production process to have an understanding of how to determine whether or not a certain kind of steel can be used for a given application.

Steel is a crucial component in the manufacturing industry and has a wide range of applications. It can withstand a broad range of temperatures and can be molded into a vast variety of different shapes. It is beneficial to have knowledge of which kind of steel will provide the best outcomes when making or buying tools or equipment, since this information may help guide decision making.

In order to determine the level of quality contained inside steel, it is examined using a variety of methods. One of the most common methods is measuring the object’s hardness. Using a hardness gauge, this method determines the relative hardness of the specimen under investigation.

There is also the hardness value test to consider. A piece of metal is imprinted with this pattern using a specific tool as part of this method. The more it deforms, the more resistant it becomes. The degree of a material’s hardness may be expressed as a percentage of its gauge length. A comparison of the different treatment options may be done with the use of this metric.

Additional testing include the ductility test as well as the corrosion test. These tests are designed to assess the performance of the materials under a variety of weights and to examine how they respond in conditions that are representative of the actual world.

There are a few more things to take into consideration in addition to these tests. On-site inspections occur rather often in this line of work. They are not, however, considered to be conclusive. They may give you a reasonable idea of the steel’s endurance and its resistance to the effects of the environment.

If you want to know for sure whether or not the quality of your steel is high, the best way to do so is to put it through some rigorous testing. Make use of a recognized lab that specializes in testing steel. No matter the method you decide to go with, you need to be sure that the material you choose is free of any harmful contaminants. Your dimensions can be drastically off as a result of this.

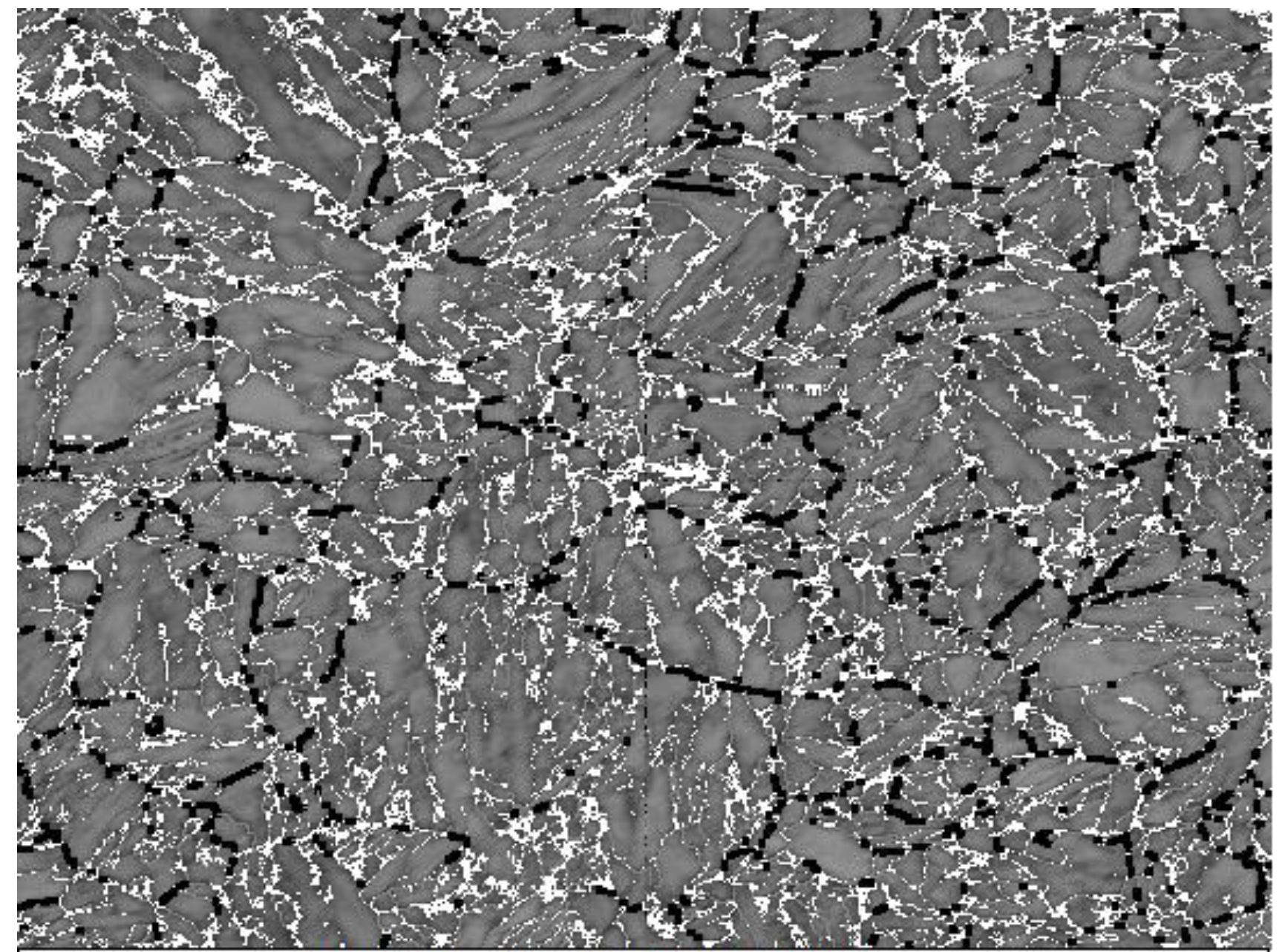

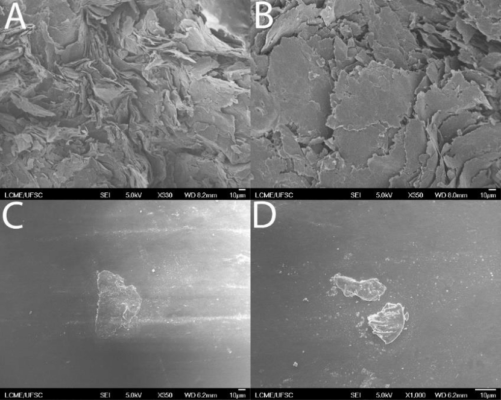

The microstructure of steel is made up of grains that range in size and have their chemical contents fluctuate as well. The phase distribution of an alloy may be determined using a program for metallurgical testing by analyzing the kind of grain and the location of the grain inside the sample.

The very last thing you need to do is go through the mill test report. In this study, the chemistry of the drug, as well as its origins and other significant data, will be discussed. This document could be requested by a customer, and it need to be backed up by an assurance of quality report.

When looking for the right kind of steel for your project, it is vital to investigate the many tests that can be performed to determine the material’s level of quality. You will be able to make more well-informed decisions if you are familiar with the benefits and drawbacks of each testing procedure.

Hardness and strength are the primary factors that decide how long a piece of metal will last and how well it will operate. A material’s ductility may be determined by these tests in addition to its abrasion resistance, and vice versa. If you do the necessary hardness test, you will be able to ensure that the appropriate kind of steel is used for your project.

When assessing the tensile strength of steel, there are primarily two procedures that are used. The tensile strength of a material is expressed as pounds per square inch (lbs/in) as the unit of measurement. A material with a low tensile strength is more brittle, meaning it is more likely to shatter under tension. In contrast, higher tensile values suggest that the material is more ductile than it is rigid.

Elongation is often employed as a supplemental measure of ductility, in addition to tensile strength, which is the most common metric. In addition to this, it may be used to locate laminations, a kind of defect that can be found in steel.

The amount of carbon that is present in steel is one of the most important factors that determines whether or not it is brittle. For you to avoid making use of materials that won’t hold up over time, it is essential to have a solid understanding of the percentage of carbon that is included in the material.

There are a few different approaches of taking measurements of the amount of carbon that is present in steel. In order to make an accurate assessment of the properties of a metal, you will need to be instructed in the proper use of the relevant equipment. For instance, you need to be able to calibrate the dial gauge, which for measuring hard metals requires a diamond point.

The use of a break test is yet another way that may be used to ascertain the level of steel’s hardness. Either a flame made of oxyacetylene or a machine may be used to cut it into the desired shape.

The file test is an old method that was used to determine the level of hardness of steel. It is not as exact as other tests, but it may produce results ranging from quite soft to glass-hard depending on the substance being examined.

Steel has a wide variety of desirable characteristics. These characteristics vary from how hard steel is to how easily it can be formed. It is a kind of metal that may be found in a wide variety of tools and even some common home appliances. The most common kinds of steel are those with high carbon content, low carbon content, and alloying elements. In order to fulfill the requirements of your project, you will need to choose the appropriate material.

There are four major classes of steel, which are referred to as medium, high, low, and alloy. Carbon, which is a component that hardens, is present in varying concentrations in each of the four kinds. High-carbon steel will be the most durable material, but it will also have the lowest degree of malleability. Stainless steel is a kind of steel that is often used for the construction of kitchen appliances.

The addition of alloys to steel may give it new properties, such as increased resistance to corrosion and the capacity to be hardened. In addition to this, they have the potential to improve the heat-treatment capabilities of steel. It’s possible that they’re made out of very strong metals, which gives them an edge when it comes to withstanding blows and being able to make clean cuts. They have a variety of potential uses, including usage in electrical wiring and as heat exchangers in industrial settings.

The medical industry and the kitchen both make substantial use of stainless steel products. Chromium and cobalt are the elements that make up this substance. Manganese and silicon are further elements that may be found in steel. Stainless steel, in addition to being resistant to corrosion and scratches, also has the ability to maintain its shape even when heated to high levels.

In addition to these components, steel also has chromium, molybdenum, and sulfur in its make-up. These are mixed with steel in order to enhance both its brittleness and its malleability. Because it strengthens the material and makes it more resistant to corrosion, molybdenum is a particularly useful element.

In addition, alloys have the potential to improve the weldability of steel. Because of this, the material’s weldability and its resistance to stress are both affected.

The American Society for Testing and Materials (ASTM) publishes the specifications for steel (ASTM). A three-digit number is used to indicate the existence of alloying elements, whereas a four-digit code is used to identify the major component in the organization’s system of classification.

It’s possible that the grading system varies from country to country. The SAE grading system, for instance, uses steel numbers with four digits and stainless steel codes with three digits.

There are four basic kinds of steel, each of which finds use in a different industry. The physical and chemical properties of each variety are unique, and these differences may have an effect on how well the finished product functions. Even if it is feasible to determine the level of a material’s hardness, it is of the utmost importance to be familiar with the features of each grade before making a selection for the project.

A standardized method for identifying and categorizing steel has been devised by the American Society for Testing and Materials (ASTM). In order to signify the steel’s notional carbon content, the organization uses a series of numerals. The depth to which the steel will harden is denoted by the grade by the letter “H,” which is appended to the end of the grade.

The fundamental martensitic grade may be heat-treated and has phosphorous and nickel added to it to improve machinability. In addition to being magnetic, this sort is ideal for components that require to have great strength and lifespan. It is used in a variety of settings, including the construction of high-stress components.

Grade of Martensitic Stainless Steel: This grade of stainless steel has a higher chromium content, which contributes to an increase in its resistance to corrosion. Punches and tools for riveting are often made of this material as well. Also a fantastic solution for surgical equipment. This grade is also employed for other purposes, such as the building of naval hulls and the blades of steam turbines.

This particular kind of steel exhibits magnetic properties and is resistant to oxidation. In addition to this, they have a high level of resistance to stress corrosion cracking. Applications in the automobile industry and the cosmetic industry use them often. In addition to that, you may get them in grades that are duplex. They combine austenitic and ferritic components, which results in an improvement in both the strength of the material and its resistance to corrosion. These grades may be obtained from mills upon request and special order.

This steel is an excellent choice for use in a variety of die applications, including forming dies, blank dies, and other fundamental tool and die uses. This grade is excellent for normal production since it has a low tempering temperature and a good resistance to wear.

This grade of A2 tool steel is superior than O1 in terms of both its machinability and its size stability. Dies, punches, mandrels, gauges, and rolls all stand to gain a great deal by making use of it. In addition to this, it is the ideal material for economical production.

Grade with an 80,000 Minimum Yield: This steel grade offers good welding and forming characteristics, as well as a low carbon content and a high manganese content. Additionally, it has minute amounts of vanadium and columbium in its composition.